SIGMASOFT® Thermoplast

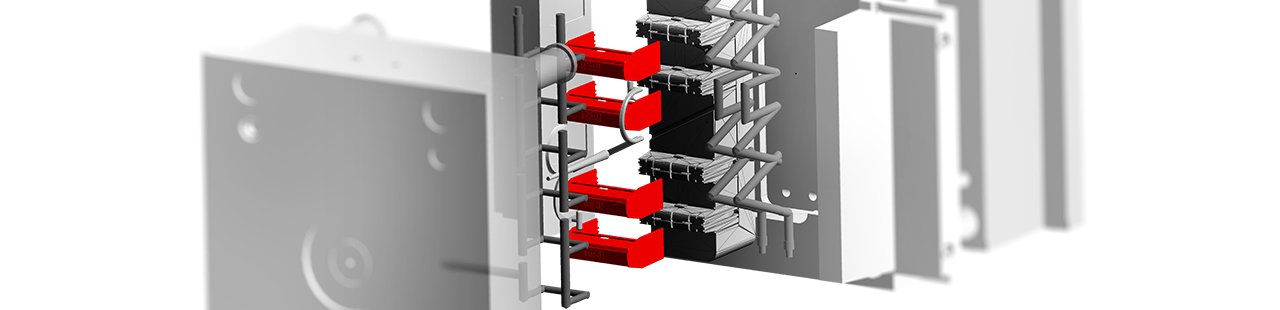

As the only software package available in the market to effortlessly integrate the complete mold information within the simulation, SIGMASOFT® delivers an unmatched degree of accuracy in the molding behavior prediction of thermoplastic materials. Beginning with a simple part design followed by first concepts for tempering layouts up to virtually testing a complete mold configuration, SIGMASOFT® delivers reliable results to base decisions on by including the real thermal behavior of the molding system in 3D.

The Thermoplast module includes the following features (click to expand):

- Filling, packing and cooling simulation of thermoplastic polymers

- Fiber orientation of fiber-reinforced materials

- Crystallization prediction of semi-crystalline materials

- External cooling and heat treatment after molding

- Shrinkage and Warpage analysis of the part inside and outside of the mold (including contact pressure of the mold)

- Core and insert deformation during filling and packing

- Influence of the ejector pins on the part deformation

- Multi-component simulation

- Optimization of tempering concepts in the mold

- Analysis of the energy efficiency

Virtual molding instead of injection molding simulation: because the mold matters!

As a part is developed, several decisions about the mold configuration must be made:

- How should the tempering layout look like?

- Which cycle time can be achieved with different cooling concepts?

- Is there potential to make the mold more energy-efficient?

- Which mold concept will lead to a part with the requested dimensions and quality?

SIGMASOFT® is a comprehensive and easy-to-use software to answer those questions. Not only the behavior of the part but also the energy balance of the mold can be analyzed and optimized. In order to speed up the development process, to ensure an adequate part quality in the first shot and to optimize the manufacturing costs, SIGMASOFT® predicts the behavior of the mold before it is even built.

SIGMASOFT® uses an intuitive graphical user interface to guide the user through the setup step by step.

An intelligent meshing algorithm generates a 3D mesh for a complete mold within less than 5 minutes. No mesh stitching or triangle moving is necessary, not even for an entire system. The possibility to load in complete mold geometries allows SIGMASOFT® to truly look into the process.

Outstanding engineering at your service

Success in plastic injection molding simulation calls for direct contact between users and a competent engineering team, with a solid technical background in plastics. Our strong and effective support network, a committed after-sales service and an application-oriented group of developers work closely with you to increase your profit.

Virtual Molding

For a good prediction of what happens on the machine it is important to take into account not only the part, but also the full mold and process. We call this approach SIGMASOFT® Virtual Molding.