SIGMASOFT® LSR

SIGMASOFT® is the market leader in the simulation of liquid silicone rubber (LSR) applications. Beyond the simulation of filling and curing, it is the only software in the market able to effortlessly integrate the complete mold information within the simulation, so that the impact of tempering concepts, processing times and inserts can be evaluated. Its highly developed 3D solver technology allows simulating precisely complex flow effects, such as jetting or plug-flow, and it reliable predicts the flow and curing behavior of thick-walled parts.

The LSR module includes the following features (click to expand):

- Prediction of the filling behavior

- Prediction of flow front propagation, fountain flow, plug flow behavior and jetting effects

- Calculation of curing and scorch, also during filling

- Cold runner functionality

- Cascade injection

- Multi-component simulation

- Prediction of shear imbalances

- Evaluation of low viscosity LSRs

- Clamping force calculation

- Holding (packing) simulation

- Effect of the exothermic reaction during curing on the temperature distribution

- Effect of the curing reaction on the viscosity

- Curing time and curing degree (cross-linking) at every location of the part

- Air traps location

- Simulation of electrical heaters in the mold with coupled PI control

- Effect of insert pre-heating and insert material in the curing behavior

- Post-curing outside the mold and external tempering (2nd heating cycle)

- FEM Interface to MARC, Ansys, Abaqus, etc.

Virtual molding leads you to increase your profit

In the LSR industry there are several topics that have a direct impact on the mold productivity and part quality:

- Where to place the heating cartridges?

- How many heaters should be placed?

- How much power is required for each cartridge?

- Is there premature curing during filling?

- How can the curing time be reduced?

- Are there cold spots in the mold?

- Is the isolation between the cold runner and the part effective?

- Where should thermocouples be placed?

SIGMASOFT® is a comprehensive and easy-to-use tool to answer those questions. With the technology of Virtual Molding, it reproduces exactly the same working conditions as in the machine and runs several cycles one after other. The electrical heaters can be simulated exactly as in reality, with all the information about their material, power and control system. In this way, the thermal layout of the mold can be understood and optimized.

SIGMASOFT® uses an intuitive graphical user interface to guide the user through the setup step by step. An intelligent meshing algorithm generates a 3D mesh for a complete mold within less than 5 minutes. No mesh stitching or triangle moving is necessary, not even for an entire system. The possibility to load in complete mold geometries allows SIGMASOFT® to truly look into the process.

Outstanding engineering at your service

Success in LSR injection molding simulation calls for direct contact between users and a competent engineering team, with a solid technical background in plastics. Our strong and effective support network, a committed after-sales service and an application-oriented group of developers work closely with you to increase your profit.

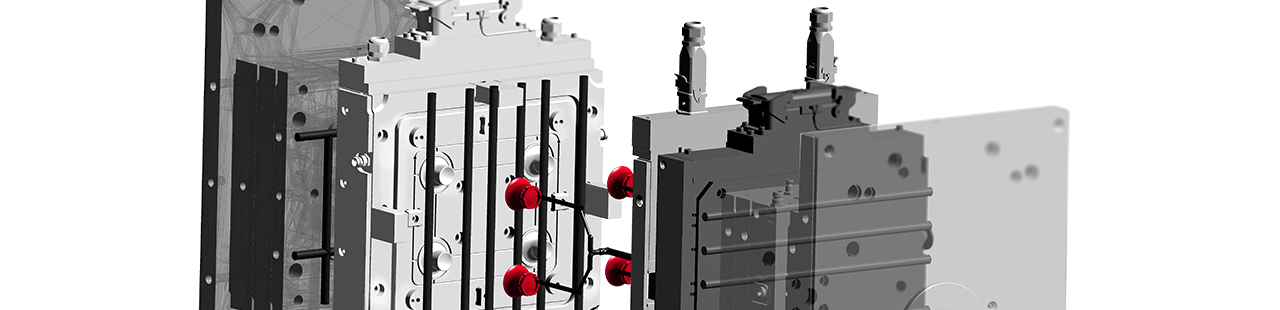

- Example in picture by courtesy of Rico Elastomere Projecting GmbH

Virtual Molding

For a good prediction of what happens on the machine it is important to take into account not only the part, but also the full mold and process. We call this approach SIGMASOFT® Virtual Molding.